Filters

A beer dispensing system, often also called a dispensing system or beverage dispensing system, is the prerequisite for filling beer from beer kegs, for example kegs, into drinking glasses. Good quality should always be ensured here, as several factors need to be taken into account for a perfect result:

- Temperature

- Carbon dioxide content

- Tap pressure

A professional dispensing system is standard in a restaurant, bar or pub. However, a high-quality beer dispensing system with the right accessories will also ensure a great atmosphere at any party at home. Tapping your own beer is not only fun, the result can also be convincing in terms of flavour and makes the barley juice from bottles and even from the popular can kegs look old. However, it is important to have a high-quality dispensing system, the right settings and a little practice. With the offers in our online shop, you can always be sure that you are only buying premium products in brewery quality at the best price. We are also available by telephone to provide you with advice and assistance - benefit from more than 25 years of experience in the field of beverage taps and accessories.

How does a beer dispensing system work?

Tapping systems or dispensing systems all work very similarly. The beer hose and the pressurised gas line, which is connected to a CO2 cylinder, are connected to the beer keg via the keg cap (or dispensing head). A pressure reducer allows the carbon dioxide (CO2) to flow into the beer keg so that both the carbon dioxide is formed in the beer and the beer is forced through the beer hose via a riser pipe at the outlet of the tap head. In this way, the beverage reaches the actual dispensing system, where it is usually cooled wet by a dry beer cooler or beer cooler and can be tapped at the beer or tap. Incidentally, a 2 kg bottle ofCO2 is sufficient for around 500 litres of freshly tapped beer.

Everything for beer dispensing from a single source

As a long-standing supplier of beverage taps and accessories, we offer everything "from keg to glass" in our online shop. In addition to tapping systems, tap heads and beer coolers, we also offer everything you need for cleaning beverage tapping systems. Compare our prices in what is probably the largest online shop for beverage dispensing systems and accessories. We always try to offer you the best price on the Internet. If you find the same item cheaper on the Internet, please contact us.

Wet cooling unit / AFG cooling unit 6-pipe, 60 litres/h

Wet cooling unit / AFG cooling unit 6-pipe, 60 litres/h with water level indicator Combi, trace and continuous cooling in one appliance. Continuous tap capacity: 60 litres/hour at 10° C TD Line: 6 Water tank: 17 litres Ice bank: 6.5 kg, 2,176 kJ (520 kcal) Cooling capacity: 739 W / 2,660 kJ/h (636 kcal) Voltage: 230 V / 50 Hz, 400 W, 2.6 A Compressor: 1/3 HP Housing material: Stainless steel Dimensions W/D/H / Weight: 543/355/415 mm / 29.5 kg 6 m climbing height, 20 m cable run Accompanying cooling UTK or OTK

Wet cooling unit BN 500 4-pipe, 500 litres/h continuous cooling, ice water generation, water bath cooling unit

Wet cooling unit BN 500 4-pipe, 500 litres/h Continuous cooling, ice water generation, Waterbath cooling unit - Cooling coils of your choice Please specify: NW 10 mm! Stainless steel housing Ready to dispense in 120 minutes. The footprint is no larger than the size of a EURO pallet. This makes transport easy despite its heavy weight. Can also be used individually for industrial cooling thanks to the different cooling coil configurations, the trace cooling pump and the control unit. Two separate refrigeration circuits. Even if one compressor fails, continues to cool at 50% capacity. Continuous flow volume of 800 l/h (increases due to ice bank in surge operation)! Continuous dispensing capacity: 500 L/h at 10° C TD Pipe diameter: NW 10 mm or 15 mm Pipes: 4 x beer Pump: 6/18/2 x 18 m head Ice bank: 100 kg/800 litres, 33,440 kJ/h (8,000 kcal/h) Cooling capacity: 5.815 W/ 20,900 kJ/h (5,000 kcal/h) Voltage: 230 V, 50 Hz, 2,560 W, 14 A Compressor: 2 x 1 1/3 HP Dimensions 10 mm appliance: W/D/H 900/1,200/805 mm Weight 10 mm appliance: 160 kg ALSO AVAILABLE WITH STRONGER PUMPS FOR AN ADDITIONAL CHARGE

Wet cooling unit, 2-pipe, 100 litre/h Combi cooling unit, heat tracing and continuous cooling in one unit with

Wet beer cooler Beer dispenser 100 litres/hour Lines: 2 x beer Pump: 6/18 m head, 20/30 m pipe run Water tank: 45 litres Ice bank: 14 kg, 4,681 kJ/h (1,120 kcal/h) Cooling capacity: 1,390 W/ 5,004 kJ/h (1,195 kcal/h) Voltage: 230 V, 50 Hz, 835 W, 6 A Compressor: 1/2 HP Appliance dimensions: W/D/H 600/405/605 mm Weight 7 or 10 mm appliance: 48 kg With ice bank approx. 90 litres additional dispensing capacity in surge mode! Built-in flow and return for use as an accompanying cooler DELIVERY WITHOUT TAPS OPTIONAL Use as an over-the-counter cooler with dispensing taps from 55 mm threaded connection possible! You can find the matching dispensing taps HERE

Wet cooling unit, 2-pipe, 200 litres/h Combi cooling unit, heat tracing and continuous cooling in one unit

Wet cooling unit, 2-pipe, 200 litres/h Combi cooling unit, ambient and continuous cooling in one unit Pipes: 2 x beer DELIVERY WITHOUT HOLES Pump: 6 m headroom, 20 m pipe run Water tank: 44 litres Ice bank: 18 kg, 6,019 kJ/h (1,440 kcal/h) Cooling capacity: 2,560 W/ 9,216 kJ/h (2,201 kcal/h) Voltage: 230 V, 50 Hz, 1.450 W, 8.5 A Compressor: 1 HP Dimensions 7 mm appliance: W/D/H 780/500/655 mm Weight 7 mm appliance: 75 kg Dimensions 10 mm appliance: W/D/H 740/500/610 mm Weight 10 mm appliance: 75 kg With ice bank approx. 144 litres additional dispensing capacity in surge mode! Use as an over-the-counter cooling unit OPTIONAL All dispensing taps from 55 mm threaded connection possible! Built-in flow and return for use as an accompanying cooler

Wet cooling unit, 4-pipe, 200 litres/h Combi cooling unit, heat tracing and continuous cooling in one unit Bit

Pipes: 4 x beer DELIVERY WITHOUT TAPS Pump: 6 risers, 20 pipe runs Water tank: 44 litres Ice bank: 18 kg, 6,019 kJ/h (1,440 kcal/h) Cooling capacity: 2,560 W/ 9,216 kJ/h (2.201 kcal/h) Ice bank provides approx. 144 litres of additional dispensing capacity in batch mode OPTIONAL Use as an over-the-counter cooling unit All dispensing taps from 55 mm threaded connection possible! See chapter Dispensing taps Voltage: 230 V, 50 Hz, 1,450 W, 8.5 A Compressor: 1 HP Dimensions 7 mm appliance: W/D/H 715/395/655 mm Weight 7 mm appliance: 76 kg Dimensions 10 mm appliance: W/D/H 780/425/655 mm Weight 10 mm appliance: 76 kg

Wine cooler, wine flow cooler, wine barrel with 3 taps

Wine cooler, wine flow cooler, wine barrel with 3 taps Dry cooler for wine, wine barrel with 3 taps 40 litres/h Supplied with drip tray. The housing offers space on the side for product advertising. The cooling coils of different lengths ensure differentiated cooling of the various types of wine. With 3 pre-set beverage lines for white wine, rosé and red wine. Beverage line 4 mm! Dimensions: W/D/H 308/410/408 mm (D=580 mm with drip tray) Weight: 29 kg Dispensing capacity: 40 l/h 230V, 50Hz, 190W, 1.6 A Wine barrel with 3 taps Pressure reducer N2 and nitrogen on site,

Wine tap X2

Wine tap X2 black CR 7 mm manual Threaded spigot 55 mm. Use plastic connection spout or stainless steel SK-168-009

Wing nut 1/2" nickel-plated brass

Beer Wing fittings Wing nut 1/2“ Brass nickel-plated ATTENTION: STAFF PRICES NOTE!!! (see below)

Wing nut 3/4" nickel-plated brass

CO2 Wing fittings Wing nut 3/4“ Brass nickel-plated ATTENTION: STAFF PRICES NOTE!!! (see below)

Wing nut 5/8" nickel-plated brass

Wing nut 5/8" nickel-plated brass Beer wing fittings, wing nut 5/8 inch, nickel-plated brass ATTENTION: NOTE GRADUATED PRICES!!!

Working pressure gauge for Co2 pressure reducer

Working pressure gauge for Co2 pressure reducer Working pressure gauge for Co2 pressure reducer Connection 1/4" AG Input at 6 o'clock Selectable version: 0-6/3 bar, 0-10/7bar

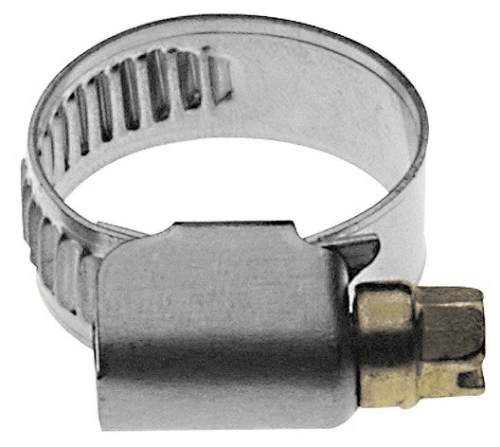

Worm drive clamps bandwidth 9 mm

Stainless steel worm drive clamps Band width 9 mm, for hoses: 10 - 16 mm, for 7 mm hoses 12 -22 mm, for 10 mm hoses

Y-piece for pipe cleaning

Y-piece for line cleaning For the simultaneous connection of 3 beer lines in the cellar during line cleaning. 2 x 5/8" external thread, 1 running nut 5/8", to be used with double winch nipple or cleaning hose for extension (not included).

Yoke fitting with knurled screw

Yoke fitting with knurled screw 0.156”, grey order no. JF156 1/2”, BSF, red order no. JF12 7/16”, UNF, black order no. JF716 SK-168-002