Design and function of a beer cooler

July 8, 2024

Beer dispenser, beer cooler

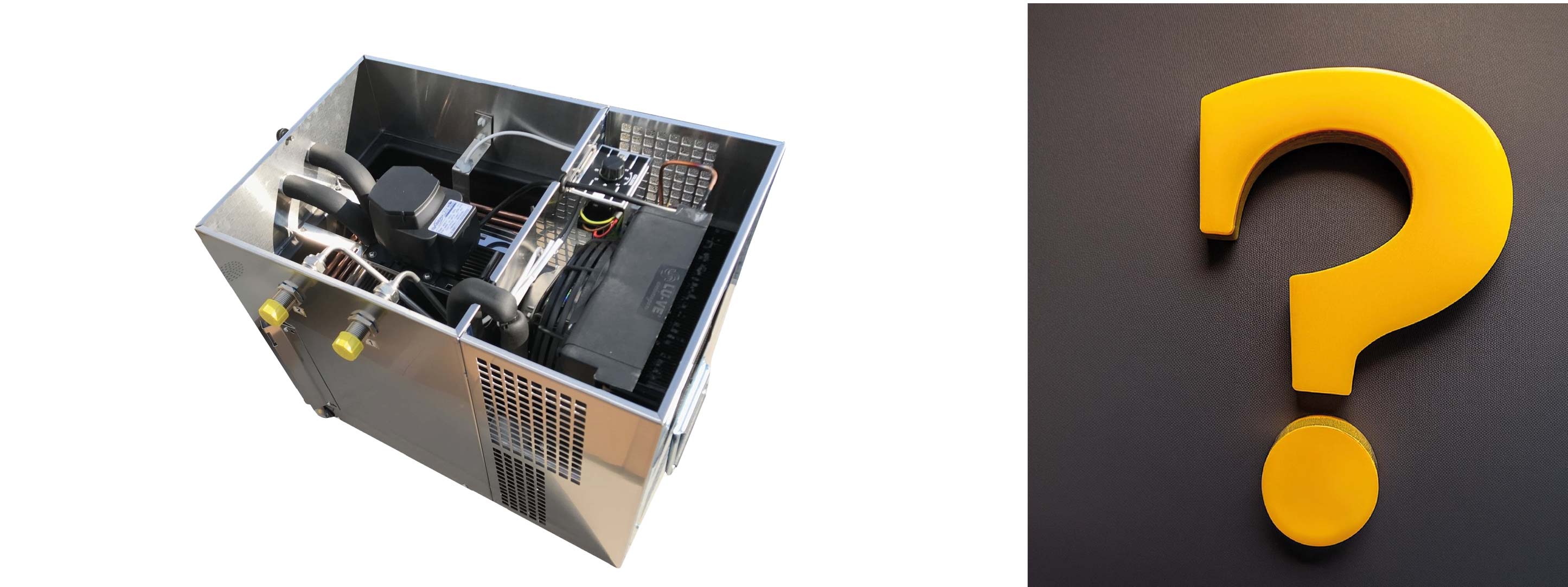

Design and function of a beer cooler

Explanation of the principle of a continuous flow beer cooler

Beer is one of the most popular alcoholic drinks in the world and is enjoyed by millions of people every day. But before it reaches the glass, it needs to be cooled to achieve the perfect flavour and optimum temperature. This is where the beer cooler comes into play.

Structure

A beer cooler is a device that is used to cool and maintain beer at a certain temperature. There are different types of beer coolers(drum pre-coolers, drum boxes)but the beer flow cooler is one of the most commonly used. This article will focus on the function and design of a continuous flow beer cooler.

A continuous flow beer cooler consists of a closed system filled with a refrigerant. The refrigerant is a gaseous or liquid substance that is used to cool the beer. The refrigerant is pumped into an evaporator via an electric compressor. The refrigerant pipe is wound together with the beer pipe. The beer is cooled to the desired temperature and can then be tapped from the cooler.

Function

The function of the beer flow cooler is based on the principle of heat transfer. When the refrigerant is passed through refrigeration pipes, it gives off heat and vaporises. The vapour is then pumped through a compressor into the condenser, where it is cooled and condenses back into liquid. The liquid refrigerant is then pumped back into the evaporator to close the cycle.

In a cooler, a refrigerant normally flows through the evaporator. The refrigerant is a substance with a low boiling point that absorbs heat during evaporation and changes its physical state from liquid to gas. The evaporator consists of a pipe or a system of pipes with fins that provide a large surface area.

When the warm medium to be cooled (e.g. beer) flows through the evaporator, it transfers heat to the refrigerant. The refrigerant is heated by the heat exchange and begins to evaporate. In the process, the refrigerant absorbs the heat and removes it from the system.

The cooled vapour of the refrigerant is then fed to the compressor, where it is compressed and pressurised. The refrigerant is then sent to the condenser, where it releases the heat energy and condenses again. The process is then repeated and the refrigerant is returned to the evaporator to continue the refrigeration cycle. Another important component of the continuous beer cooler is the electrical control system. The control system(Thermostat for beer cooler)is responsible for monitoring and regulating the temperature in the cooling system. If the temperature is too high, the compressor switches on to activate the refrigerant and cool the beer. If the temperature is too low, the compressor switches off to prevent overcooling.

There are different types of beer flow coolers that are suitable for different applications. For example, there areBeer flow cooler for home usewhich are usually small and portable and suitable for use at parties and events. There are also larger beer flow coolers that are suitable forUse in bars and restaurantsand have a higher capacity.

Components

A beer cooler consists of various technical components to keep the beer at a cool and pleasant temperature. Here are some possible components that could be found in a typical beer cooler:

- KompressorThe compressor is the centrepiece of the cooling system. It compresses the coolant and generates the necessary pressure to produce the cooling effect.

- Evaporator: The evaporator is a heat exchanger located inside the beer cooler. This is where the coolant evaporates and extracts the heat from the beer, cooling it down.

- Condenser: The condenser is another heat exchanger located outside the beer cooler. Here, the coolant releases the heat into the environment and condenses back into liquid.

- Thermostat: A thermostat is an electronic component that measures the temperature in the beer cooler and switches the compressor on or off as required to maintain the desired temperature.

- FanA fan can be used to improve the air circulation in the beer cooler and support heat dissipation.

- Insulation: To improve the efficiency of the beer cooler, it is usually fitted with insulation. This keeps the cold inside and prevents the ingress of warm air from outside.

- Lines and pipes: These are used to transport the refrigerant between the compressor, the evaporator and the condenser.

It is important to note that the exact composition and functionality of a beer cooler can vary depending on the model and manufacturer. However, the components listed above are some of the common components used in many beer coolers.

Conclusion

To summarise, a continuous flow beer cooler plays an important role in the cooling of beer. It is based on the principle of heat transfer and consists of a closed system with a refrigerant, an evaporator, a compressor, a condenser and an electrical control system.

The operation of the beer flow cooler allows the beer to be cooled and maintained at the desired temperature, which is essential for optimum flavour and a pleasant drinking experience. There are different types of beer flow coolers suitable for different applications, from smaller portable units for home use to larger units for use in bars and restaurants.

A good beer flow cooler is an essential item for any beer lover or restaurateur who wants to serve their guests a cool and refreshing beer. It is important to pay attention to the quality of the appliance to ensure a long service life and reliable performance.

Please contact us and together we will find the right continuous flow beer cooler for you. Benefit from our many years of experience. Get in touch with us now:+49 (0)2271989630-0or by email:verkauf@getraenkezapfanlagen.net

Order beer flow coolers now and enjoy freshly tapped beer.