CO2 pressure reducer - function, design and area of application for beer, sparkling water and aquariums

July 10, 2024

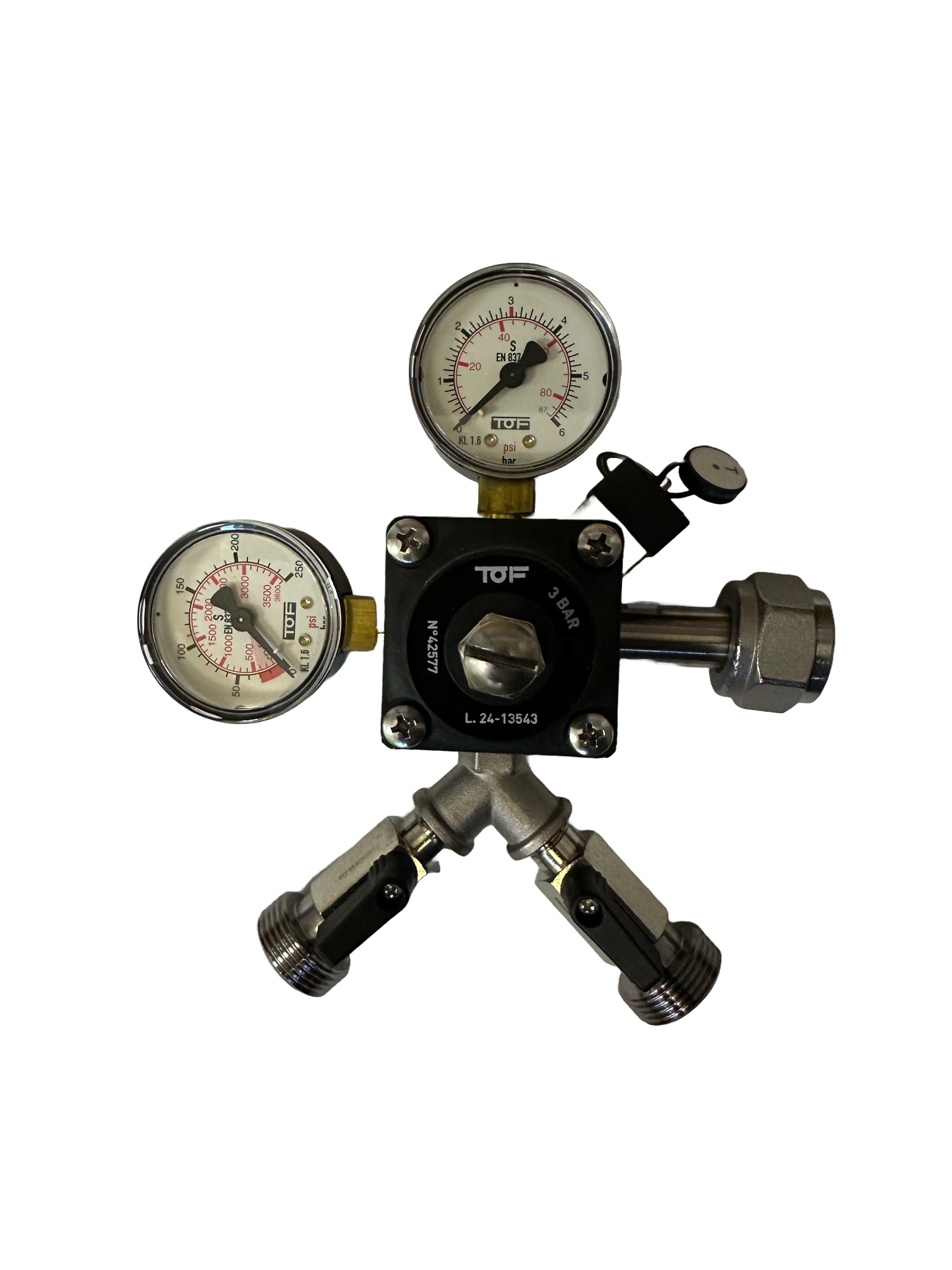

CO2 pressure reducer for dispensing system

CO2 pressure reducer - regulates the pressure!

CO2 pressure regulators are an important element in various applications where CO2 is required in certain quantities. They help to reduce the pressure of the gas to ensure constant and precise dosing. In this article, we will take a closer look at how CO2 pressure reducers for beer, sparkling water and aquariums work, how they are constructed and where they are used.

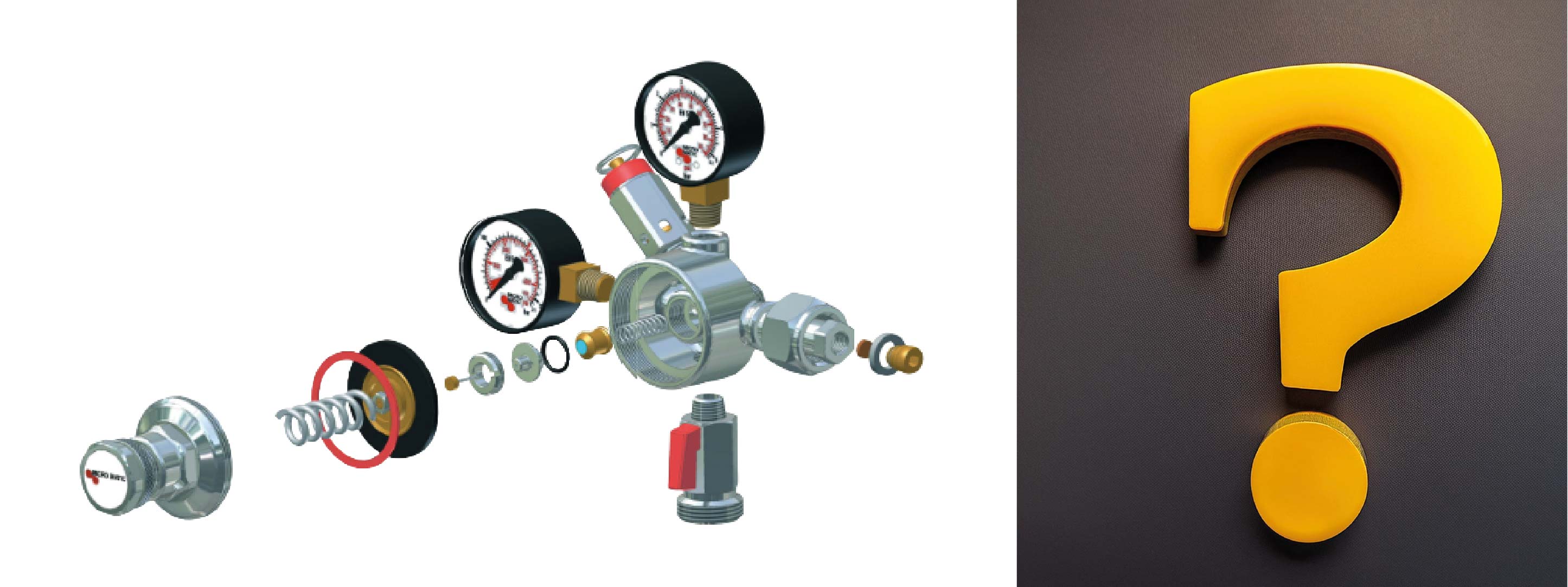

Function and structure

CO2 pressure regulators usually consist of a housing, a pressure gauge, a control valve and an outlet for the CO2 flow. The housing contains the control valve, which regulates the pressure of the CO2 gas to enable accurate dosing. The pressure gauge indicates the pressure of the gas within the system, allowing the system to be monitored. The CO2 outlet is fitted with a hose nozzle to which a hose can be connected and the operation of CO2 pressure reducers is based on Bernoulli's equation, which states that the pressure in a fluid system is inversely proportional to the velocity of the fluid. In a CO2 system, this means that the pressure in the system is inversely proportional to the flow rate. The higher the flow rate, the lower the pressure in the system. The CO2 pressure reducer is used to reduce the pressure in the system to a constant value, regardless of the flow rate.

Field of application

Beer

CO2 pressure reducers are used in various areas of application. One of the most common areas of application is beer production. CO2 is added during the fermentation process to carbonate the beer and improve the flavour. The CO2 pressure reducer ensures that the CO2 gas is fed into the beer at a constant pressure to ensure even carbonation.

Sparkling water

Another area of application is the production of sparkling water. CO2 is used here to carbonate the water and make it sparkling. The CO2 pressure reducer ensures that the CO2 gas is fed into the water at a constant pressure to ensure even carbonation.

Aquaria

CO2 pressure reducers are also used in aquariums. Here, CO2 is introduced into the water to promote the growth of plants and the health of fish and other creatures in the aquarium. The CO2 pressure reducer ensures that the CO2 gas is fed into the water at a constant pressure to ensure even distribution in the aquarium.

Co2 pressure reducer for beer tapping systems

In a beer dispensing system, the CO2 pressure reducer plays an important role in beer dispensing. The beer must have a certain carbon dioxide pressure in order to form a sufficient amount of foam and improve the flavour. The CO2 pressure reducer is responsible for reducing the pressure of the CO2 gas to the correct level and ensuring an even dosage of the gas. The CO2 pressure reducer is mounted on the Co2 cylinder and reduces the Co2 cylinder pressure to the appropriate working pressure for the dispensing process. The reduced pressure is indicated by the pressure reducer's pressure gauge and can be adjusted as required. The CO2 gas then flows through a pipe from the CO2 pressure reducer into the beer keg. When the beer keg is tapped, the CO2 gas flows through the beer and ensures an even delivery pressure. A pressure relief valve in the CO2 pressure reducer regulates the pressure in the keg and ensures that the beer is not over-carbonated. Another important aspect of the CO2 pressure reducer in a beer dispensing system is the ability to monitor and adjust the pressure in the system. Too low a pressure can lead to insufficient carbonation, while too high a pressure can over-carbonate the beer and affect the taste. The CO2 pressure reducer allows the operator to monitor and correctly adjust the pressure in the system.

Conclusion

CO2 pressure regulators are an important component in various applications where CO2 is required in certain quantities. They help to reduce the pressure of the gas and ensure constant and precise dosing. The way they work is based on Bernoulli's equation, which states that the pressure in the system is inversely proportional to the flow rate. The CO2 pressure reducer is used to reduce the pressure in the system to a constant value, regardless of the flow rate.

To summarise, CO2 pressure regulators play an important role in various applications where CO2 is required in certain quantities. They ensure precise and constant dosing of the gas and thus guarantee uniform carbonation or distribution in the system. CO2 pressure reducers are an indispensable tool for those working in beer production, sparkling water production or aquaristics who require precise dosing of CO2.

Please contact us and together we will find the right Co2 pressure reducer for you. Benefit from our many years of experience. Get in touch with us now:+49 (0)2271989630-0or by email:verkauf@getraenkezapfanlagen.net

Order your Co2 pressure reducer now and enjoy freshly tapped beer at home: